El Lamination One-stop Solution

Our company is currently a domestic production base that produces a relatively complete range of silicon steel sheets.

Hot Products

Modern ERP & Smart Factory Operations

In 2015, Tianxiang began its upgrade toward modern information management by implementing an ERP system across the workshop. Today, intelligent equipment is fully applied in production and warehousing, with a WMS integrated with smart storage and logistics solutions. Technologies such as barcode/QR, RFID, sensors, vision/laser navigation, indoor positioning, and machine learning support automated in/outbound handling, dynamic dispatching, and route optimization.

Solar Power & Green Factory Commitment

Tianxiang promotes green energy and is building a sustainable green factory with an 8,000 m² solar power system rated at 1,200 kW. With an average daily generation of about 5,200 kWh, it supplies up to 80% of the company’s electricity needs. This reduces carbon emissions and lowers operating costs, enabling us to offer more competitive pricing while supporting long-term sustainable development.

Industries We Serve

Precision silicon steel cores for transformers, motors, inductors, appliances, automotive, and industrial control worldwide.

Committed to building the world’s silicon steel core supermarket

Jiangyin Tianxiang Electrical Appliances Co., Ltd. was established in 1990. The company currently covers an area of more than 35,000 square meters and a building area of 18,000 square meters. It is currently the production base with a complete range of silicon steel sheets in East China. There are more than 160+ employees, including 38 professional and technical personnel with bachelor’s degree or above and 6 engineers. There are several professional management personnel.

The company has introduced: 200T, 160T, 125T, 110T, 80T, 65T, 60T, 45T, 30T, 25T, closed gantry double points, C-type double points, three-way guide pillar single point, different series. There are more than 60 high-precision and high-speed stamping machines in total. There are a total of 88 manual punching machines, with a monthly 600T heat treatment capacity and electromagnetic performance testing conditions, and can meet the production needs of iron cores of any size.

Employees

Technical personnel

Production experience

Awards won

Testimonials

Real feedback from global customers—quality, lead time, support, and performance you can trust.

“Consistent lamination quality and very low burrs. Our transformer efficiency improved after switching.”

Premium Silicon Steel Cores, Made to Order

Order EI/UI laminations and motor cores with fast lead times, stable quality, and custom sizes—request a quote now.

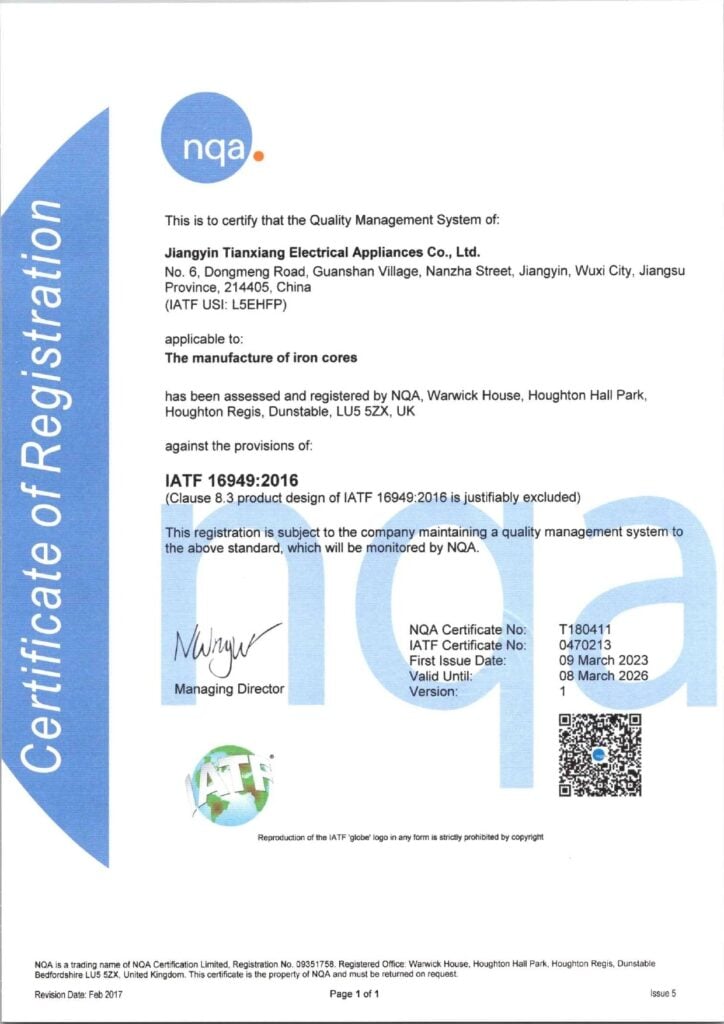

Quality Certification

Standardized QC system ensuring stable process control and consistent product reliability.

Company News

Latest updates on our production, technology, events, and exhibitions—see how Tianxiang keeps improving for customers.

Tianxiang Annual Meeting: Growing Stronger with Smart Manufacturing and Green Energy

At Jiangyin Tianxiang Electrical Appliances Co., Ltd. (Tianxiang), our annual meeting is more than a celebration—it is a moment to review real progress, thank the

What Makes the EV Motor Core a Critical Component in Electric Vehicles?

As the global automotive industry accelerates toward electrification, a critical yet often overlooked component is taking center stage in innovation and performance: the EV motor core.

Optimizing Transformer Efficiency with High-Quality Core Laminations: The Tianxiang Advantage

Introduction: Why Core Laminations Matter for Transformer Performance In today’s competitive transformer-component market, the quality, precision, and engineering of the core laminations play a vital role in

Understanding Stacked Riveting vs Butt Stacking for Transformer Cores

Designing a high-performance transformer begins with careful attention to the core structure. Among the many decisions that shape efficiency, reliability, and long-term performance, one of

Annealing Transformer Cores: Why It Matters for Efficiency

In power transformers, small material decisions can have outsized impacts on long-term performance. Among these decisions, annealing of transformer cores is one of the most

Reducing Core Loss in Transformer Laminations for Higher Efficiency

In modern power systems, transformers are expected to deliver high efficiency, long service life, and stable performance under increasingly demanding operating conditions. Among the various